Prototype on lifting and moving containers in a container yard

After building the container grabbing mechanism, time has come to move the container around:

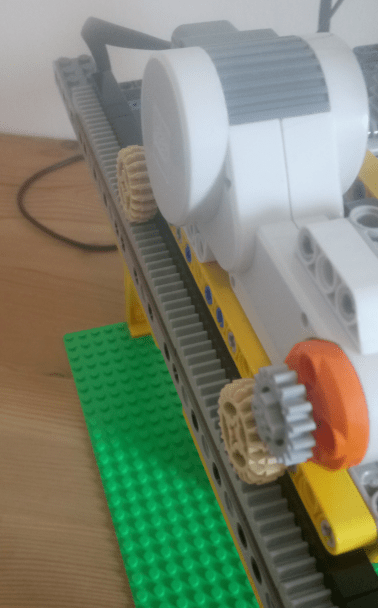

The lifting mechanism is designed using rack and pinion gears, distributed in four corners, to increase stability. The grabbing mechanism has the rack mounted, and the pinions are mounted on the overhead crane, enclosing the grabbing mechanism, to make it more stable.

The reason for having the pinions on the overhead crane, and not on the grabbing mechanism, is simply to make the grabbing mechanism lighter by not having another motor mounted on it.

Another design consideration is to have the same number of gear interfaces from the motor to both sides of the pinion/racks. At my first iteration, the motor was driving one side of the pinions directly, while the motion was directed to the pinions on the other side by gears and shafts. However, since there is some slack in the gears, it introduced a delay in the reaction of pinions on the other side, and the grabbing mechanism was lifted unevenly and wobbly. In the final prototype the motion is first directed to the center, and then directed to the two sides. There is still a slack and delay, but is evenly across the two sides.

The overhead crane has the weight of the motors evenly split on the two sides, moving as much weight as possible away from the center and reducing the need for reinforcement of the crossbeams.

The movement in X-direction/crosswise is very simple. A motor, gear and racks in one side, and wheels on the other side, running on a smooth surface. The wheel side has a slight delay in reaction, as it is being “dragged” by the gear/rack side.

To solve this, there would have to be gear/rack on both sides, and the equivalent number (and ratio) of gears between the motor and racks on both sides – same principle as with the grabbing mechanism described above. For now, I decided that the lag on the wheel side is manageable, but I might correct it later, if the crane turns out to be too imprecise.

I experimented with several truss designs for the beams on which the overhead crane is resting on, but I ended up with using the 5×7 liftarms w/ open center, supported by a few other liftarms. This is lighter, but still sturdy.

The next steps will be to create the basis for moving the overhead crane in the X-direction/lengthwise, and introduce some kind of optical recognition/barcode for the containers, so the system can store the information on which containers are stored where.