Modelling a German semaphore train signal, and operate it “by wire”

A railroad need signals, and adding signals to a LEGO® railroad layout bring a sense of realism to the operation. Since I currently live in Germany, and previously been modelling with the German railroad history as model, the signals will be German style.

We were on a small weekend-escape south of Hamburg this September, and we were staying just next to the regional “Heidebahn” railroad between Buchholz and Hannover, close to the station of Handeloh. There, I came across these – in my mind – beautiful operational semaphore signals.

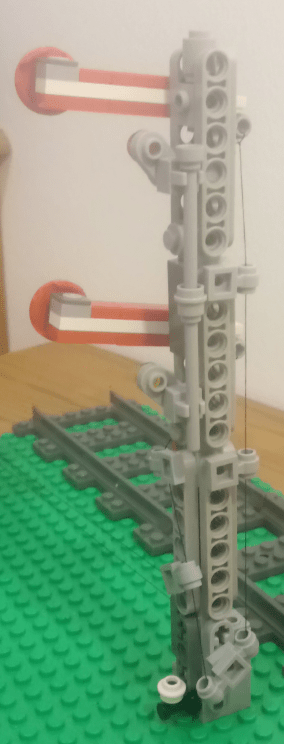

The left signal is the Main Signal (Hp “Hauptsignal”) , capable of showing drive, slow and stop. The right signal, with the orange/white circle is a Distant Signal (Vr “Vorsignal”), showing what to be expected from the signal further down the line. Read more about the different states/aspects of the German signalling system on Wikipedia

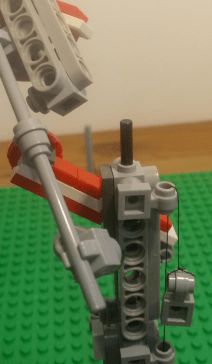

I found two main challenges. The first was to make the footprint of the arms as small as possible, while still keeping the red-white-red line true to model and keeping the arms free to move. For this, I did a ‘hack’, using a 3L bar for pivoting, and leaving a hole of one plate high + half stud wide in the arm. In this way, it was possible to keep the arm footprint 1 stud wide and 1 brick high. My first idea was to use a 1×1 Technic brick w/hole for fastening the arm to the mast, but that would require at least 1 brick + 1 plate high – and it didn’t look good.

The other challenge was the mast itself. I would like to make it as slim as possible, while still showing the lattice structure. I used thin 1×6 technic liftarms to mimic the lattice, and put them on 1×1 modified brick, stud on all 4 sides, securing them with some bars trough the open studs.

At the end of both arms towards the mast, “wires” are attached, which then run down on the side of the mast, and can be used for operation the arms.

I am not completely satisfied with the look, and I have some ideas of reducing the footprint, while keeping the lattice impression, using a 180 degree SNOT (read about SNOT here)

Another good looking option would be using the out-of-prduction and rather expensive train signal support lattice, or the newer (slightly cheaper) support lattice mast. The 1 x 4 x 1 fence might also be usable.

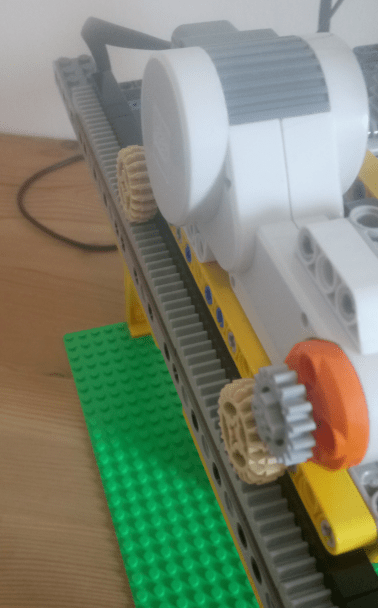

The final result can be seen below. Another post in near future will be about motorizing the Semaphore signals!

The pictured stand can handle both vertical and landscape photos, without the supporting structure obstructing the motive.

The pictured stand can handle both vertical and landscape photos, without the supporting structure obstructing the motive.